You can contact LEARNZ, part of CORE Education, at:

Postal Address:

PO Box 13 678,

Christchurch 8141,

New Zealand

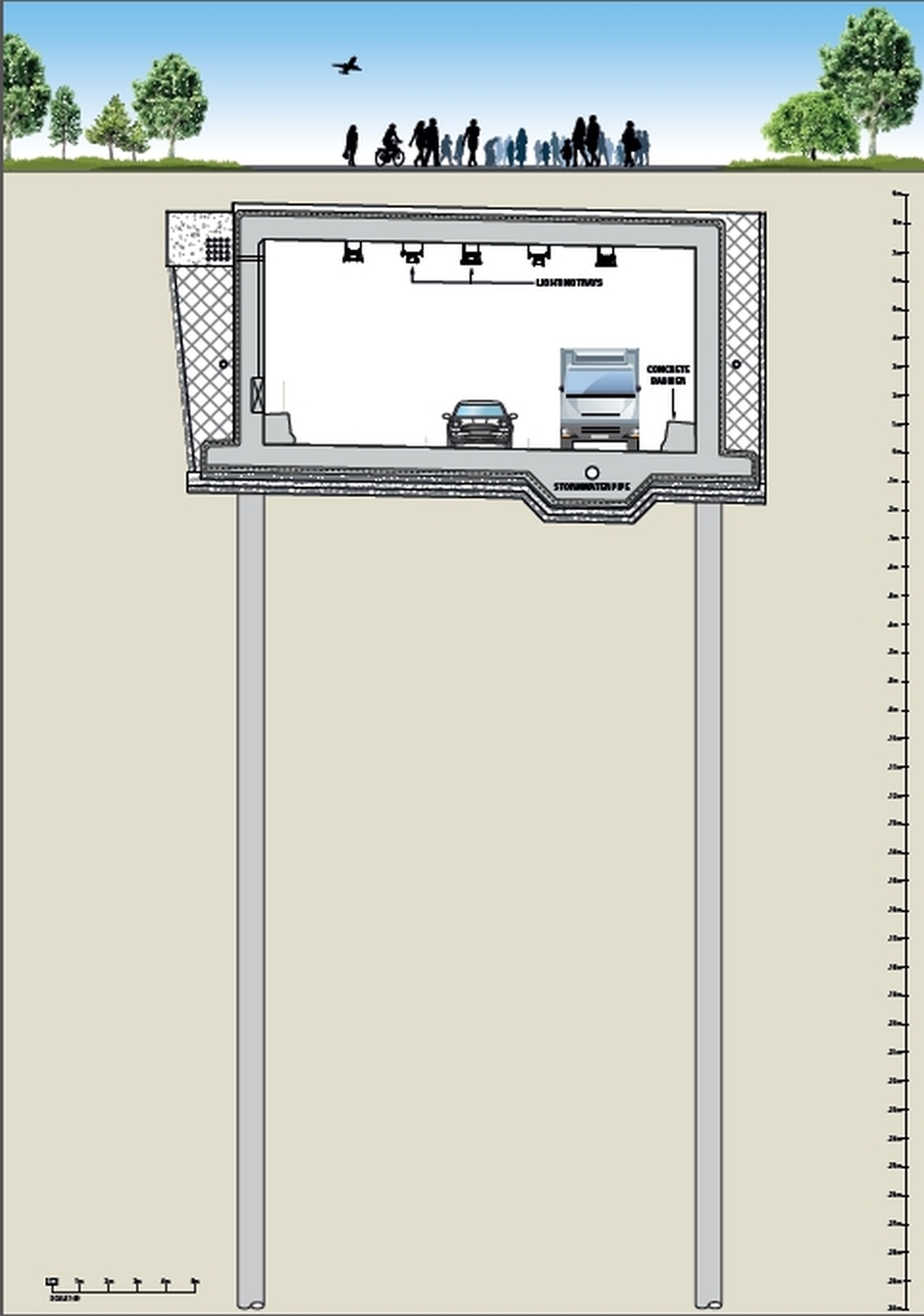

A lot of work must be done to design a safe tunnel, prepare the site, and move underground pipes.

Digging deep into Buckle Street

A 300 metre long trench has been dug into Buckle Street.

Many pipes carrying services to homes and businesses are buried in the ground beneath Buckle Street.

These pipes carry;

These services have to be moved out of the way so the trench can be dug for the new tunnel and road;

Underneath Buckle Street is a 100 year-old sewer pipe;

The tunnel and the road for the National War Memorial Park Underpass have been designed with people’s safety in mind.

The engineers are making plans in case there is an accident or car breakdown in the tunnel;

A wall protects the workers and keeps the soil in place while the tunnel and road are being built

Keeping safe is important on the work site.

,Digging begins for the underpass construction site trench. Image: NZTA.

,The tunnel is being constructed as a concrete box in a trench and is known as a ‘cut and cover’ project. It is not being burrowed through rock. Image: NZTA.

The tunnel will be anchored to 30-metre deep concrete piles to protect it in case of a major earthquake. Image: NZTA.

Discuss two challenges in completing Memorial Park. How were these challenges managed?